Uncoated GRP

Our “best seller” GRP used as central strength member or armouring with diameters from 0,40mm to 4,00mm at 0,10mm units and meter marking every 2 meters for diameters above 1,00mm => monthly capacity 50 000km

Uncoated GRP Rods (0,4~4,0mm) Characteristics

| ITEM | UNIT | SPECIFICATION | TEST METHOD |

|---|---|---|---|

| Appearance | Shall be Good | Good | – |

| Diameter Tolerance | mm | dia. ± 0.05 | Micrometer |

| Specific Gravity | g/mm2 | 2.0 ~ 2.2 | ASTM D 792 |

| Tensile Strength | Kg/mm2 | Min. 130 | ASTM D 3916 |

| Tensile Modulus | Kg/mm2 | Min. 5000 | ASTM D 3916 |

| Elongation at Break | % | Min 2.5 | ASTM D 3916 |

| Flexural Strength | Kg/mm2 | Min. 140 | ASTM D 790 |

| Flexural Modulus | Kg/mm2 | Min. 5000 | ASTM D 790 |

| Coef. of Thermal Expansion | /℃ | Nom. 7*10-6 | – |

| Minimum Bending Radius | mm | 25 X Dia | – |

| Glass Content | % | Min. 80 | – |

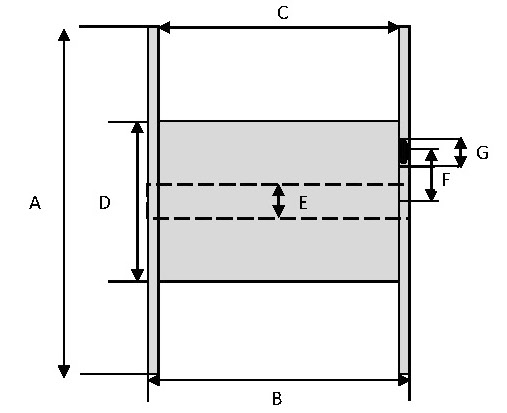

Drum Dimensions

| GRP DIAMETER | A | B | C | D | E | F | G | LENGTH |

|---|---|---|---|---|---|---|---|---|

| 0.4~0.8 | 500 | 316 | 250 | 320 | 57 | 85 | 53 | 50 Km |

| 0.9~1.2 | 650 | 455 | 401 | 300 | 80 | 130 | 40 | 50 km |

| 1.3~1.7 | 800 | 560 | 494 | 400 | 80 | 160 | 40 | 50 km |

| 1.8~2.0 | 900 | 560 | 494 | 400 | 80 | 160 | 40 | 50 km |

| 2.1~2.2 | 1000 | 480 | 560 | 400 | 80 | 160 | 40 | 50 km |

| 2.3~4.0 | 1100 | 560 | 480 | 400 | 80 | 160 | 40 | 50 km* |

GRP Dia 2.7~3.0mm_37.8 Km

GRP Dia 3.1~3.7mm_25.6 Km

GRP Dia 3.8~4.0mm_15.0 Km